Welcome to our comprehensive guide on PCB Design and Via Holes! This guide provides you with easy-to-understand information about different types of via holes, such as Conventional, Blind, and Buried Vias, and their roles in establishing connections between different layers in a PCB. Learn why it's crucial to protect vias located near QFN and BGA components. We'll also delve into advanced via options, including Tenting, Filling, Plugging, Stacking, and Staggering, while highlighting the methods used for their protection. We appreciate your patience, so let's dive into the fascinating world of Via Holes in PCB Design!

(ii) Blind Via

(i) Conventional Via : Conventional vias are the most commonly used type of vias in PCB designs. They establish connections that span the entire PCB, going from the top layer to the bottom layer and vice versa. In the case of a multilayer PCB, this connection extends from the first layer to the last layer. We've already provided detailed information about conventional vias on the previous page, so we won't delve deeper into their specifics within this article. Refer to Fig. 16.

(ii) Blind Via : At this point, our understanding is clear: vias establish connections from one layer to another. Similarly, blind vias offer the same functionality, but they are restricted to creating connections from the outer layer to the inner layers rather than spanning the entire PCB from top to bottom. This means that a blind via connects the top layer to an inner layer without extending throughout the entire PCB. In simpler terms, a blind via is visible on either the top or bottom side, but not from both sides. The concept will become clearer upon referencing Figure 17, shown below.

(iii) Buried Via : Buried vias serve the purpose of establishing connections solely between inner layers. They are not linked to any of the outer layers. This signifies that on an actual PCB, these vias will not be visible from either the top or bottom side, as their functionality is confined to the inner layers. For a clearer understanding of the concept of Buried Vias, please refer to Figure 18 below.

Let's examine a comparison of the three aforementioned via hole types within the context of a 4-layer PCB layer structure. This will allow us to better discern the distinctions among them. Please refer to Figure 19 for a visual representation that illustrates these differences clearly.

Let's delve into the details of other types of vias based on their protection methods and advanced Via.

(a) Tented Via : A Tented Via, as its name implies, is a via that resides under a "tent" of solder mask ink. This means that the via hole pads are not left open on the actual PCB surface. Tented vias are shielded by solder mask ink applied over the copper pads of the via holes. The presence of solder mask ink on these via pads serves to safeguard the vias from external damage and corrosion on the copper surface.

Moreover, this type of via protection plays a significant role during the assembly process by preventing accidental shorts when the via is in close proximity to a surface mount technology (SMT) component pad. In PCB layouts featuring tented vias, there is no necessity to create solder mask openings for the vias' pads, as the tenting effect is achieved without these openings.

To visualize this concept, please refer to the image below that demonstrates a tented via. In such cases, there's no requirement to incorporate solder mask openings for the vias' pads in the PCB layout. For a example of a tented via, please consult Figure 20.

(b)Tented + Covered Via : Sometimes, the term "tented via" doesn't necessarily imply that the holes of the via will be covered. Instead, tented vias might only cover the pads of the via holes. In situations where the via holes are very small, they can indeed be fully covered by the tented via. However, for larger via holes, a combination of tenting and coverage might be required. This means that the dry film on the hole area will be followed by complete solder mask ink application on the hole. As a result, the via hole will be entirely covered and tented with solder mask ink. Notably, the solder mask ink will not extend inside the hole walls.

This specific type of via is often used in proximity to BGA component pads, particularly to aid in the assembly process. Please refer to Figure 21 for an illustrative example of the Tented + Covered Via configuration.

(c) Filled Via - Conductive/Non-conductive : In this type of via, the hole barrels are filled with either complete non-conductive material or conductive material. This filling serves to protect the hole walls, preventing any direct exposure of the hole walls to the environment. Please refer to Figure 22 for a visual representation of this via type.

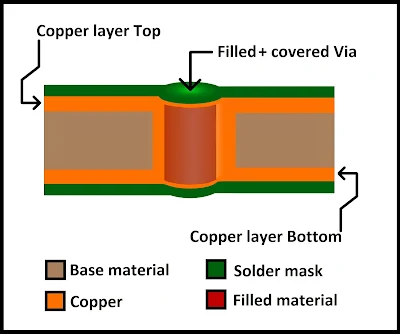

(d) Filled Via + Covered : In the aforementioned Filled Via process, where conductive/non-conductive material fills the hole barrel, the material remains exposed due to the absence of solder mask ink. However, should the need arise for coverage, the Filled Via + Covered approach must be employed. In this type, the via hole, complete with the conductive/non-conductive material filling, is also covered, including the via hole's pad area. To gain a visual understanding of this via type, please refer to Figure 23 for an illustrative example.

(e) Plugged Via : In the case of a Plugged Via, the via is partially filled with non-conductive/conductive material, but not to the extent of entirely filling the hole barrel. For an example of the Plugged Via, please refer to Figure 24.

(f) Plugged Via + Covered : Within the Plugged Via type, we provide protection to the via by partially filling it from its ends. Consequently, in the Plugged Via + Covered configuration, both the filled material within the via hole and the via hole pads are shielded by solder mask ink. In essence, this approach involves the partial filling of the via hole with Conductive/Non-Conductive material, accompanied by the application of solder mask ink on both ends of the via. For a visual depiction of this configuration, please refer to Figure 25.

(g) Filled Via + Capped (Via in Pad) : This advanced via method serves a dual purpose of conserving space while safeguarding via holes. In this via type, the hole barrel is filled with Conductive/Non-Conductive material. Subsequently, the hole's end is capped with copper pads. This design strategy allows us to utilize these spaces as via holes and utilize the capped pads as solderable pads—whether as component pads or test points. To elaborate, this involves the concept of vias positioned under copper pads or copper pads that are placed onto the via holes.

For an example of this Via in Pad configuration, please refer to Figure 26

(h) Stacked and Staggered Via : These fall under the category of Micro vias. Micro vias are smaller in size compared to mechanically drilled via holes. They are created using laser drilling techniques. Micro vias offer space-saving advantages, higher signal integrity, and generate less capacitance due to their smaller dimensions.

Stacked Via involves the stacking of one via directly onto another, with the vias in direct contact, as illustrated in Figure 27. Stacked vias can be completely filled using epoxy material.

On the other hand, Staggered Via follows a similar concept, but the holes are not directly aligned between layers. There's a slight offset from one layer's via to another's via. For an example of this type of via, please refer to Figure 28. Staggered vias can be filled with epoxy material.

Page-8 | Page-9 | Page-10